Introduction:

Industrial facilities face a myriad of challenges, and among the most critical is the potential for spills that can compromise the safety of workers and the environment. Preparedness is paramount, and selecting the right industrial spill kit is a crucial aspect of a comprehensive response plan. This blog post provides a detailed exploration of the various types of industrial spill kits, helping you make informed decisions to safeguard your workplace.

Universal Spill Kits

Universal spill kits are versatile and designed to handle a wide range of spills, including oils, coolants, solvents, and water-based fluids. These kits typically contain absorbents that can manage a variety of liquids, making them a go-to solution for facilities with diverse spill risks.

Oil-Only Spill Kits

Facilities dealing with oils, fuels, or other hydrophobic liquids benefit from oil-only spill kits. These kits repel water and selectively absorb oil-based substances, making them highly effective in environments where water contamination is a concern.

Chemical Spill Kits

Tailored for facilities working with hazardous chemicals, chemical spill kits include specialized absorbents capable of safely managing corrosive or aggressive substances. These kits often contain neutralizers to stabilize and neutralize hazardous materials.

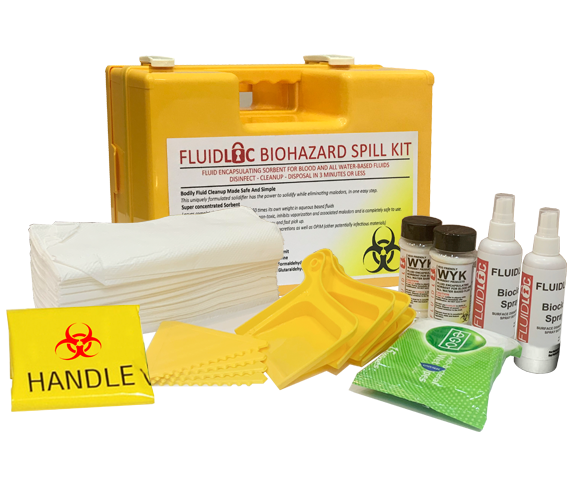

Biohazard Spill Kits

In industries such as healthcare or laboratories, where biological hazards are a concern, biohazard spill kits are essential. These kits include materials for safe containment and disposal of potentially infectious substances, ensuring compliance with health and safety standards.

Mercury Spill Kits

Facilities working with mercury or other heavy metals require specialized spill kits designed to handle these unique challenges. Mercury spill kits include materials to safely collect and contain mercury spills, minimizing the risk of exposure.

Battery Acid Spill Kits

Industries utilizing batteries, especially those with acid-based electrolytes, need spill kits designed to address acidic spills. Battery acid spill kits often include neutralizing agents to safely manage and clean up acid spills.

Railcar Spill Kits

For transportation or manufacturing facilities with the risk of spills from railcars or tankers, railcar spill kits are crucial. These kits are equipped with large-capacity absorbents and containment devices to manage spills involving significant volumes of liquids.

Conclusion

Understanding the different types of industrial spill kits is essential for creating a targeted and effective response strategy. By selecting the right kit for your specific industry and spill risks, you enhance the safety of your workplace, protect the environment, and ensure compliance with regulatory standards. Regular training on the proper use of these kits is equally important, empowering your team to respond swiftly and confidently in the face of unexpected spills. Remember, a well-prepared facility is a safer and more sustainable one.