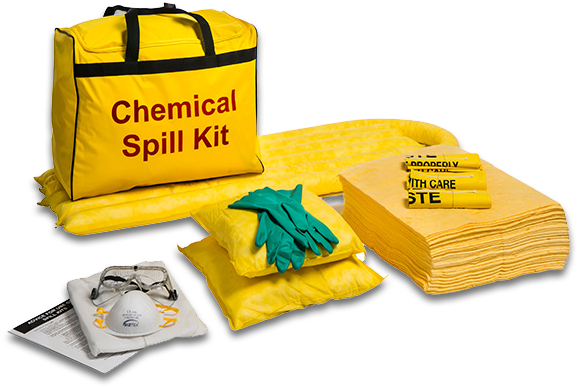

Chemical Spill Kits are the best defence against many hazards that are associated with the accidental release of hazardous substances. As your go-to containment, cleanup, and decontamination tools, the items within your spill kit will equip your staff to handle any spillage successfully. As you’re probably aware, spills involving hazardous chemicals or dangerous goods can result in serious incidents such as fires, explosions, asphyxiation, and environmental damage. Spills must be cleaned up immediately — and effectively — to reduce the likelihood of these events occurring.

This blog will cover safety tips for using the spill kit for chemicals. These tips will help you avoid any hazardous activity that can harm your health and lead to major loss of life.

1 Assess The Risk

In any case of a leak or spill, your staff should inform the manager or higher authority so that they can assess the risk and take safety measures to stop the spill from leaking. One more thing is to educate the staff about spill cases and leakage so they can be aware of the problem beforehand. Spill kits for chemicals can be dangerous for health and the company.

2 Put On PPE

Safety measures before chemical spills include kits, and the major integral part is the PPE Kit. Not only is it helpful in dangerous processes, but it also helps overcome day-to-day hurdles. So, PPE includes the required clothes, footwear, gloves, eyewear, or breathing apparatus.

3 Access The Spill Kit

A trained staff is the best way to cure any hazardous activity. They should be able to gain access to the kit relevant to the spill site. Make sure the kits are in excellent condition, fully assembled, and with no missing or damaged items.

4 Lay Down A Safety Barrier

The next step in the spill cleanup is to lay down a barrier around the spill kit for the chemicals area. Depending on the spill kit chemicals that contain your chemical product, containment barriers such as adhesive mini-booms may be used to prevent chemicals from spreading into the workplace.

5 Stop the leak

Before using spill kits, make sure you stop the leak in the organization. Every spill is different, so some involve a leaking chemical drum, while others may be uncontrolled spills that can be caused by faulty equipment. So leave the place as soon as possible so that you can face less loss.

6 Absorb the Spillage

Your chemical spill kit should be designed to contain and manage the chemical spill. Find the range of adsorbent items in your kit that you can use to soak up the spill. Absorbent items may include pads, pillows, floor sweep, or even old socks. Also, remember that each additional item may be more suitable for a particular task during the cleanup of spil chemicals.

7 CleanUp- Up the Spill, sire

The next step in the procedure is cleaning up the spill location. To ensure no lingering contamination, floors, walls, equipment, or stores need to be cleaned.

Decontaminating the scene is usually necessary following a chemical spill to ensure no hazardous material is left behind.

Ensure that the personnel can breathe safely in the spill site’s air during this cleanup phase. Large spills may release high concentrations of dangerous vapors, which must be dispersed by mechanical or natural ventilation. If the vapor levels surpass the permissible limits of the workplace exposure guidelines, there could be health risks and non-compliance.

8 Dispose of Chemical Waste

Chemical residue and trash can contaminate equipment, absorbents, booms, PPE, and other workplace objects. Chemical waste must be disposed of in the appropriate garbage bags so authorized waste management companies can collect it.

Waste bags should be tightly knotted together to prevent more spills throughout the garbage disposal procedure.

9 Report

Any incident at work must be reported if you want your company to continue operating safely and in compliance. Establish protocols for reporting spills or leaks of hazardous chemicals so your team can collaborate to reduce risks as soon as possible. To minimize the possibility of a recurrence event, we advise addressing workplace health and safety concerns during the upcoming staff meeting and taking appropriate corrective action.

Bottom Line

We hope that by providing you with the essentials of a spill kit, you will be able to clean up and decontaminate your site, regardless of whether you’re dealing with a split IBC that is spilling toxic chemicals over your loading dock or a small container of flammable liquids that was dropped on your workshop floor. This blog could be the foundation for your staff training on spill kits. Additionally, remember to write your instructions. These should be laminated and stored with each spill kit for your company.